Introduction

Background on CCW

What is a Title V Permit?

Timeline of Events to Date

Link to Draft Permit Document & VCAN Outline of Permit Content

Issues Allegheny County Health Department seeks Public Comment on 1/10/24

1. Introduction

The Allegheny County Health Department (ACHD) issues a Title V Operating Permit to US Steel’s Clairton Coke Works (CCW) every five years. The current Title V Permit has been revised in a draft form in the process of being reissued.

ACHD is required by the United States Environmental Protection Agency (EPA) to receive public comment about the wording of the draft Title V Permit. ACHD will receive statements from Allegheny County residents:

Wednesday, January 10, 2024 at 6:00 pm

Clairton Municipal Building

551 Ravensburg Blvd., Clairton, PA 15025

This document will give you direct links to the draft ACHD permit document to read for yourself. We will also provide you with an outline of the draft Permit’s language and the six key issues we believe ACHD will accept public comment on. If your statements stray from these specific issues, it is our experience in testifying at previous ACHD Title V hearings that what you say may not be considered by ACHD or the EPA.

We think this process is complicated, with many pieces to consider. As a result, we have scheduled a public meeting to make a presentation and then discuss these issues with local residents at:

CEDCC @ 6:00pm

282 St. Clair Avenue, Clairton, PA 15025.

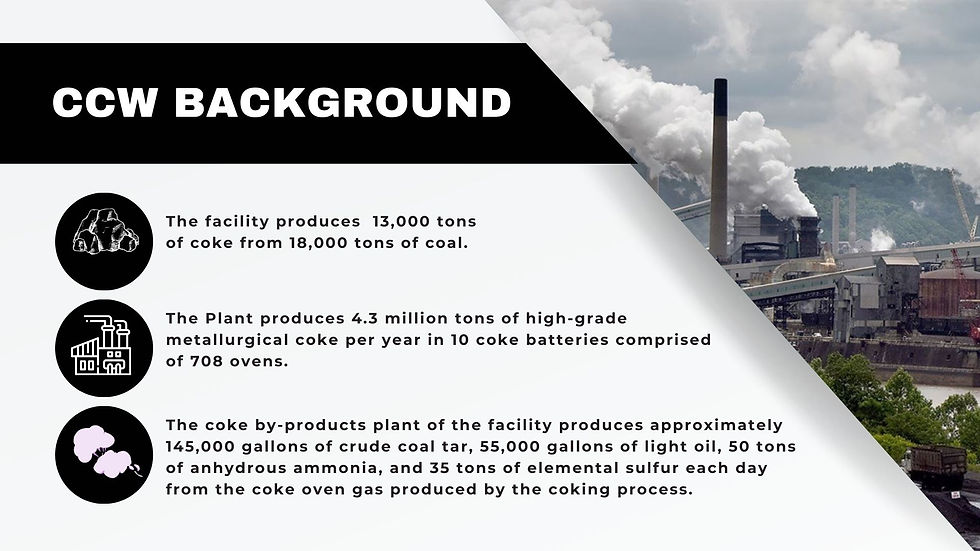

2. Background on Clairton Coke Works

“The U.S. Steel Mon Valley Works Clairton Plant in Allegheny County, Pennsylvania is the largest by-products coke plant in the United States. The facility was built in 1901, and U.S. Steel has operated the facility since 1904. The facility operates seven coke batteries, seven quench towers, and six boilers, among other emission units. The facility produces approximately 13,000 tons of coke per day from the distillation of more than 18,000 tons of coal.

The coke by-products plant of the facility produces approximately 145,000 gallons of crude coal tar, 55,000 gallons of light oil, 50 tons of anhydrous ammonia, and 35 tons of elemental sulfur each day from the coke oven gas produced by the coking process. The coke produced is then used in blast furnace operations in the production of molten iron for steel production.

The Clairton facility is a major source of carbon monoxide (CO), nitrogen oxides (NOw), particulate matter (PM), PM10, PM2.5, sulfur dioxide (SO2), volatile organic compounds (VOCs), and Hazardous Air Pollutants (HAPs).”

Quote from US Environmental Protection Agency Administrator Michael Regan’s September 21, 2023 Order, page 6. Attachment A.

3. What is a Title V Permit?

The EPA has identified “hazardous air pollutants” whose releases have to be controlled by government regulators. The Federal Clean Air Act (CAA) calls individuals or businesses that produce these chemicals “sources. These sources must be “permitted” by the EPA to release a maximum amount each year. Title V of the CAA spells out what information has to be contained within each permit that lasts five years. As a result, it is called a Title V Permit.

Across our country, it is actually state government agencies who enforce the terms of the Title V permit on a day to day basis. EPA and state governments create a State Implemented Plan (SIP). Pennsylvania’s enforcement agency in our SIP is the PA Department of Environmental Protection (PA DEP). Pennsylvania also has our own statute, the Pollution Control Act, that restricts releases of hazardous air pollutants inside Pennsylvania.

Pennsylvania law is unique because our two largest counties (based upon population) Philadelphia and Allegheny, were given the primary responsibility to enforce the CAA and Pollution Control Act inside their borders. The Allegheny County Health Department (ACHD) has the responsibility to negotiate and enforce Title V Permits inside our county. As a result, ACHD is called the “primary air pollution control enforcement agency.” Allegheny County has its own law restricting hazardous air pollutants in our country called "Air Pollution Control Regulations'' or "Article XXI''.

As the Federal Government’s agency, EPA oversees and has the final say on the entire Title V process.

Here are the federal, state and local air quality agencies and links to the three laws they each are responsible to enforce:

US Environmental Protection Agency – Overview of the Clean Air Act and Text

PA Department of Environmental Protection- Air Pollution Control Act, Purdons’ Title 35 Health & Safety; Chapter 23

Allegheny County Health Department – Rules & Regulations XXI

4. Timeline of Events to Date

In 2012 U.S. Steel first obtained a Title V permit for Clairton Coke Works (CCW).

September 26, 2016, U.S. Steel submitted an application for renewal of CCW’s Title V permit.

January 13, 2022 ACHD published notice of draft permit, subject to a public comment period that ran until February 28, 2022, and was extended to March 15, 2022.

September 28, 2022, ACHD submitted the Proposed Permit to EPA 45-day review for approval. ACHD withdrew this Permit and then resubmitted the Second Proposed Permit to EPA for its 45-day review and approval on November 16, 2022.

January 3, 2023 EPA's 45-day review period ended with no objections. As a result, ACHD’s Second Proposed Permit for CCW was considered approved.

March 6, 2023 Environmental Integrity Project, Penn Environment & Clean Air Council filed Claims A thru H as Objections with EPA to Second Proposed Permit. Group Against Smog & Pollution (GASP) filed Claim I with EPA as an additional Objection to Second Proposed Permit.

September 21, 2023 EPA Order by Administrator Regan accepted some Objections & denied other Objections, forcing ACHD to rewrite Second Proposed Permit.

October 11, 2023 Tribune Review Article “Environmental Groups Claim Victory in EPA Ruling on US Steel plant in Clairton”

ACHD has now revised the Second Proposed Permit to follow the EPA October Order. We believe these revisions are written into a December 6, 2023 document on their website. ACHD has scheduled a Hearing in Clairton on January 10, 2024 to collect public comment on the revised Second Proposed Permit.

Date issued | Source name | Description | Fine/penalty |

1/14/2020 | United States Steel (USS) – Clairton | Visible emissions and opacity | $743,625 |

2/21/2020 | United States Steel (USS) – Clairton | Failed Compliance Test | $13,200 |

5/28/2020 | United States Steel (USS) – Clairton | Demand for Stipulated Penalties Under Settlement Agreement and Order #190604 | $361,400 |

|

|

|

|

1/25/2021

| United States Steel Corporation, Clairton Works, Edgar Thomson Plant | Failure to meet stack test compliance limits | $8,800 |

2/19/2021

| United States Steel Corporation, Clairton Works, Edgar Thomson Plant | Failure to submit required reports and release of air contaminants | $4,165 |

3/12/2021

| United States Steel (USS) – Clairton

| Demand for Stipulated Penalties Under Settlement Agreement and Order # 190604 | $383,450 |

4/1/2021

| United States Steel (USS) – Clairton

| Notice of Violation for hydrogen sulfide exceedances from 2020 and 2021 YTD | Notice of 33 days in violation; possible penalty $25,000 per day |

6/4/2021

| United States Steel (USS) – Clairton

| Demand for Stipulated Penalties Under Settlement Agreement and Order #190604 | $201,500 |

8/27/2021

| US Steel - Clairton Works

| Release of Anhydrous Ammonia - Violation of General Prohibition of Pollution | $5,500 |

8/27/2021

| US Steel, Clairton Works

| Enforcement Order

| $5,500 civil penalty |

12/6/2021

| US Steel – Clairton | Visible emissions violations | Inspection Report |

12/15/2021 | US Steel – Clairton | Permit Violation | $5,500 civil penalty |

|

|

|

|

1/28/2022

| U.S. Steel (Clairton Plant) | Modification Order for Submitted Episode Rule Mitigation Plan |

|

3/03/2022

| U.S. Steel (Clairton Plant) | Demand Letter for Stipulated Penalties | $859,300 |

3/07/2022 icon Google Directions

| U.S. Steel (Clairton Plant) | Enforcement Order – H2S Emissions: 2020 46 violations 2021 94 violations 2022 13 violations 153 violations | $1,842,530 civil penalty |

3/24/2022

| U.S. Steel (Clairton Plant) | Enforcement Order – Uncontrolled Pushes | $4,570,000 civil penalty |

11/28/2022 | United States Steel (USS) - Clairton | Demand for Stipulated Penalties Under Settlement Agreement and Order #190604 | $458,225 |

|

|

|

|

7/11/2023 | United States Steel (USS) – Clairton | Demand for Stipulated Penalties Under Settlement Agreement and Order #190604 regarding 3rd Quarter 2022 | $301,225 civil penalty |

3/15/2023 Demand for | US Steel - Clairton Works

| Stipulated Penalties Under Settlement Agreement and Order #190604 Section IX. Stipulated Penalties | $307,800 |

|

| Approximate total | $10,071,520 |

Introduction and Overview: This section includes general information about the permit, including its scope and purpose. We recommend you read the actual permit. You can use the link above to the ACHD website.

General Terms and Conditions: This section outlines the standard regulatory requirements and compliance measures that the CCW must adhere to under the Title V Operating Permit.

Emission Unit Level Terms and Conditions:This is crucial for the facility's compliance with environmental regulations and standards, ensuring that the CCW operates within the permissible limits of emissions and follows best practices for environmental protection. This section is comprehensive, detailing specific operational and environmental compliance conditions for different emission units within the facility.

Equipment Requirements: Specifications for equipment like compressors, pumps, and pressure relief devices, focusing on their design and operational requirements to minimize emissions. This includes the use of seal systems, barrier fluid systems, and specific operational parameters to prevent leakage and emissions.

Monitoring and Testing: Detailed procedures for monitoring and testing of equipment to ensure compliance with emission standards. This involves regular inspections, leak detection using specific methods (such as Method 21), and performance testing of control systems and equipment.

Leak Detection and Repair: Protocols for detecting leaks in various components like valves, pumps, and connectors, along with timelines and procedures for repairing detected leaks. The document specifies concentration thresholds for identifying leaks and the expected actions following their detection.

Compliance with Specific Regulations: Adherence to various subsections of the Code of Federal Regulations (CFR), particularly those related to hazardous air pollutants (HAPs), volatile organic compounds (VOCs), and specific substances like benzene. These regulations dictate how the facility must manage and control emissions from different processes and equipment.

Record Keeping and Reporting: Requirements for maintaining detailed records of operational parameters, emissions data, repair and maintenance activities, and compliance with the permit conditions. This also includes periodic reporting to regulatory authorities.

Exemptions and Alternatives: Conditions under which certain equipment or operations might be exempt from standard requirements, or where alternative methods of compliance are acceptable. These alternatives must demonstrate equivalent or better emission reduction capabilities.

Operational Unit Requirements: These include detailed operational limits, monitoring requirements, and compliance criteria for various processes and emission units. This could cover aspects like volumetric flow rates, fan motor amperes, and fugitive emissions control.

Boilers R1 and R2 (B005 and B006) and Boilers T1 and T2 (B007 and B008):

These boilers must be properly operated and maintained according to good engineering and air pollution control practices, including regular maintenance, except in cases of emergency conditions.

Ammonia Flare (B010):

The ammonia flare must be properly operated and maintained in accordance with good engineering and air pollution control practices. This includes performing regular maintenance, except during emergency conditions.

There are specific requirements for maintaining and operating the flare according to a flare minimization plan. This plan includes a listing of all process units and equipment connected to the ammonia flare, a description of the equipment and processes to reduce flaring, and an update on any new implementations to minimize flaring.

Abrasive Blasting (G001):

The permit does not specify work practice standards for this unit, except for general compliance with applicable regulations.

Cold Cleaning Machines (G002):

Operators must use covers to prevent evaporation of solvents, provide equipment for draining cleaned parts, and adhere to specific operating procedures to minimize solvent emissions.

Coal and Coke Storage Piles (E001, E002, E003):

Specific work practices for managing coal and coke storage piles, including moisture content maintenance and other handling procedures, are required to control dust emissions.

Roadways & Vehicular Traffic (F001):

There are standards for minimizing fugitive dust emissions from vehicular traffic, including the use of water sprays, dust suppressants, periodic street sweeping, and maintaining vehicle speeds below specified limits.

Boilers R1 and R2 (B005 and B006)

Restrictions on fuel types: Only coke oven gas and natural gas shall be combusted.

Emission limitations: Specific limits are set for NOx, particulate matter, and opacity of visible emissions.

Testing requirements: Emissions testing for NOx and CO is required at least once every two years.

Boilers T1 and T2 (B007 and B008)

Restrictions on fuel types: Only coke oven gas and natural gas shall be combusted.

Emission limitations: Specific limits are set for NOx, particulate matter, and opacity of visible emissions.

Testing requirements: Emissions testing for NOx and CO is required at least once every two years.

Ammonia Flare (B010)

Operation and maintenance requirements: The flare must maintain a minimum destruction efficiency of 98%.

Emission limitations for SO2, NOx, CO, VOC, and ammonia.

Testing requirements: Emissions testing performed once every five years to determine VOC destruction efficiency.

Roadways & Vehicular Traffic (F001)

Restrictions on emissions visible at or beyond the property line and limitations on opacity.

Record-keeping requirements for hours of operation and dust control measures.

Abrasive Blasting (G001)

Restrictions on the size of the area for abrasive blasting without specific permits.

Operational requirements to minimize emissions from abrasive blasting activities.

Cold Cleaning Machines (G002)

Restrictions on the operation of cold cleaning degreasers, including requirements for covers, draining equipment, and solvent management.

Coal and Coke Storage Piles (E001, E002, E003)

Restrictions on emissions visibility and opacity from the storage piles.

Requirements for maintaining specific moisture content in the coal and coke.

Miscellaneous Sources

Various other minor sources are listed, including their trivial nature and specific operational or record-keeping requirements.

These specific operational requirements are designed to ensure compliance with environmental regulations and standards, focusing on minimizing emissions and maintaining air quality. Each unit has detailed requirements tailored to its operation and impact on the environment.

Work Practice Standards and Maintenance: This section covers the required work practices for minimizing emissions, including the maintenance of equipment and control devices.

Boilers R1 and R2 (B005 and B006) and Boilers T1 and T2 (B007 and B008):

These boilers must be properly operated and maintained according to good engineering and air pollution control practices, including regular maintenance, except in cases of emergency conditions.

Ammonia Flare (B010):

The ammonia flare must be properly operated and maintained in accordance with good engineering and air pollution control practices. This includes performing regular maintenance, except during emergency conditions.

There are specific requirements for maintaining and operating the flare according to a flare minimization plan. This plan includes a listing of all process units and equipment connected to the ammonia flare, a description of the equipment and processes to reduce flaring, and an update on any new implementations to minimize flaring.

Abrasive Blasting (G001):

The permit does not specify work practice standards for this unit, except for general compliance with applicable regulations.

Cold Cleaning Machines (G002): Operators must use covers to prevent evaporation of solvents, provide equipment for draining cleaned parts, and adhere to specific operating procedures to minimize solvent emissions.

Coal and Coke Storage Piles (E001, E002, E003):

Specific work practices for managing coal and coke storage piles, including moisture content maintenance and other handling procedures, are required to control dust emissions.

Roadways & Vehicular Traffic (F001):

There are standards for minimizing fugitive dust emissions from vehicular traffic, including the use of water sprays, dust suppressants, periodic street sweeping, and maintaining vehicle speeds below specified limits.

Miscellaneous Sources:

The permit also outlines work practice standards for other minor sources, focusing on minimizing emissions and maintaining environmental compliance.

These work practice standards are crucial for ensuring the operational efficiency of the facility while minimizing environmental impacts, particularly in terms of air quality and emissions. The permit outlines specific actions and procedures that must be followed to adhere to these standards.

Record Keeping Requirements: These record-keeping requirements are critical for demonstrating compliance with the permit conditions and for providing transparency and accountability in the facility's operations. They enable regulatory bodies to monitor and ensure that the facility adheres to environmental standards and regulations. Detailed instructions on the types of records that must be maintained to demonstrate compliance with the permit's conditions, including documentation of equipment inspections, maintenance activities, and emissions monitoring.

Boilers R1 and R2 (B005 and B006), and Boilers T1 and T2 (B007 and B008)

Maintain records of the type and amount of each fuel combusted.

Record cold starts, including date, time, and duration.

Keep records of operation, maintenance, inspection, calibration, and/or replacement of combustion equipment.

Ammonia Flare (B010)

Record inspections, episodes of non-compliance with permit conditions, and corrective actions taken.

Document monthly propane usage for the flare and the daily hours of operation.

Abrasive Blasting (G001)

Maintain monthly records of the square feet of surface area cleaned by abrasive blasting.

Cold Cleaning Machines (G002)

Keep semiannual records of solvent usage, including type and amount.

Coal Storage Piles (E001), Coke Storage Pile - Peters Creek (E002), and Coke Storage Pile - South Yard (E003)

Maintain monthly records of throughput and the number of acres used each month for coal and coke storage.

Roadways & Vehicular Traffic (F001)

Record daily hours of operation and dust control measures taken.

Submit a monthly summary of dust control measures to ACHD on a semi-annual basis.

General Requirements

All records of non-compliance with the permit conditions must be recorded along with corrective actions taken.

All records must be retained by the facility for at least five years and made available to ACHD upon request.

Reporting Requirements: Guidelines on the reporting of compliance status, including the frequency and content of reports to be submitted to regulatory authorities. These reporting requirements are crucial for regulatory compliance and ensuring the facility's accountability in its operations. They enable the regulatory authorities to monitor the facility's adherence to environmental standards and permit conditions.

Semi-annual Reports:

CCW is required to submit semiannual reports to ACHD. These reports should include all required information for the reporting period and be postmarked by the 30th day following the end of the reporting period. The reports should contain:

Monthly and 12-month data as recorded under specific conditions of the permit.

Information on cold starts.

Non-compliance information required to be recorded by specific conditions of the permit.

Specific Emission Reports:

The “committee” must report each exceedance of the 30-day rolling average emission limitation for NOx and the 12-month rolling average emission limitation for NOx. The date of each exceedance must also be listed.

Fuel Combustion Reports: CCW is required to report the total monthly Fuel Combustion Unit fuel use per fuel type.

Non-Compliance and Breakdown Reporting:

Reporting instances of non-compliance does not relieve CCW of the requirement to report breakdowns in accordance with other specific conditions of the permit.

Annual Reporting for Ammonia Flare:

Monthly fuel usage and monthly hours of operation for the ammonia flare must be reported to ACHD on an annual basis.

Additional Requirements and Conditions: Any additional site-specific requirements or operational conditions that are not covered in the standard regulatory framework.

Incorporation of 40 CFR 63 Subpart DDDDD:

The National Emission Standards for Hazardous Air Pollutants (NESHAPs) for Industrial, Commercial, and Institutional Boilers and Process Heaters, as outlined in 40 CFR Part 63 Subpart DDDDD, are incorporated by reference into the permit. This means the facility must comply with these federal standards, which set emission limits and establish requirements for monitoring, record-keeping, and reporting for boilers and process heaters.

The permit specifies that ACHD shall reopen the permit to incorporate specific requirements from 40 CFR 63 Subpart DDDDD as necessary. This indicates an ongoing process of updating and ensuring compliance with the latest federal standards as they apply to the facility's operations.

Permit Shield Effect: This section that outlines the legal protections provided by the permit, indicating that compliance with the permit's terms is deemed compliance with applicable regulations.

Compliance Assurance: The permit shield asserts that compliance with the conditions of the permit is deemed compliance with applicable requirements of the Clean Air Act. This means that as long as the facility adheres to the permit's terms, it is considered to be in compliance with the relevant air quality laws and regulations.

Protection Against Enforcement: The permit shield can provide protection against enforcement action for certain emissions or operational processes if they are explicitly covered by the permit. This does not imply immunity from all regulations but assures that the facility won't be subject to enforcement for complying with the permit's terms.

Scope and Limitations: The shield is typically limited to the specific conditions and emissions outlined in the permit. It does not extend to any environmental violations outside the scope of the permit or to any future regulatory requirements that may be established after the permit's issuance.

Transparency and Accountability: The permit shield requires transparent operation and adherence to all conditions set forth in the permit. Regular monitoring, record-keeping, and reporting are integral to maintaining the shield effect.

Dynamic Nature: The permit may be modified or reopened to incorporate new standards or requirements, at which point the shield's scope may also be adjusted.

Issues ACHD is seeking Public Comment on January 10, 2024

1.Emission Limits and Types: Levels for various pollutants, including particulate matter, sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs). These pollutants can significantly impact air quality and may exacerbate asthma symptoms.

2.Operational Practices: The facility's operational practices, particularly those related to combustion, use of fuels, and processing methods, can affect the type and amount of pollutants released into the atmosphere. Operational malfunctions or non-compliance with these practices could lead to increased emissions.

3.Leak Detection and Repair: Incomplete or delayed repair of leaks in equipment could lead to unintended emissions of VOCs and other hazardous air pollutants, which could be triggers for asthma.

4.Monitoring and Testing Protocols: The frequency and effectiveness of monitoring and testing for emissions play a crucial role in ensuring compliance with permitted levels. Inadequate monitoring could result in undetected or underreported emissions.

5.Record Keeping and Reporting: Accurate record-keeping and timely reporting of emissions data are essential for regulatory compliance and public transparency. Any lapses in these areas might obscure potential air quality issues.

6.Fugitive Dust and Vehicular Traffic: Operations involving the handling of coal and coke, as well as vehicular traffic within the facility, can contribute to particulate matter in the air. Dust control measures are crucial in mitigating this risk.

.png)

Comments